What is induction sealing?

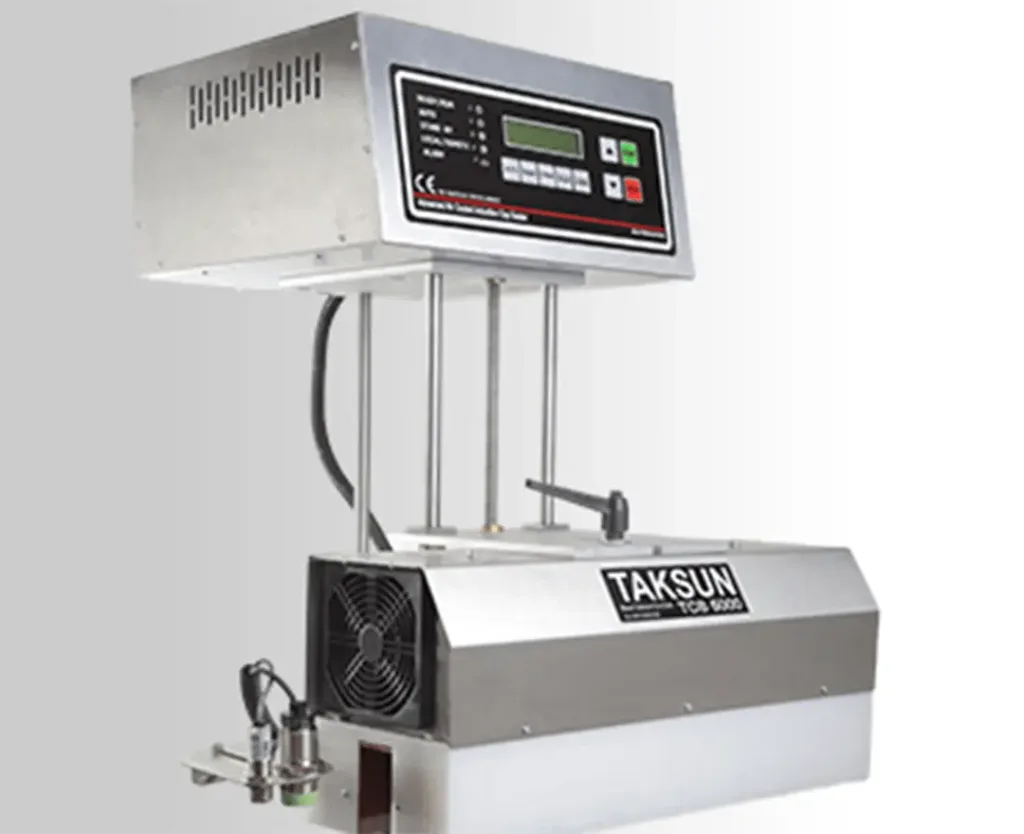

One of the best methods for sealing and tamper-proofing products is the use of induction sealing technology. The advantages of sealing products include preventing contamination, moisture, and all external factors that could damage your products. In this process, a laminated aluminum foil, which can be combined with cardboard or foam, is applied to the opening of bottles and containers. The induction sealing machine creates a safe magnetic field that affects metals, causing molecular movement in the aluminum surface. This results in an increase in the temperature of the aluminum surface, which heats the laminate and causes it to adhere to the container or bottle's opening, thus completing the sealing process.

To seal products, the following items are required:

- Bottles or containers with screw-on or press-on plastic lids

- Typically made of PET, polyethylene, PP, polyester, glass, or crystal

- A suitable and high-quality machine

- An induction sealing liner that matches the container material and is sized to fit the diameter of the lid’s bottom