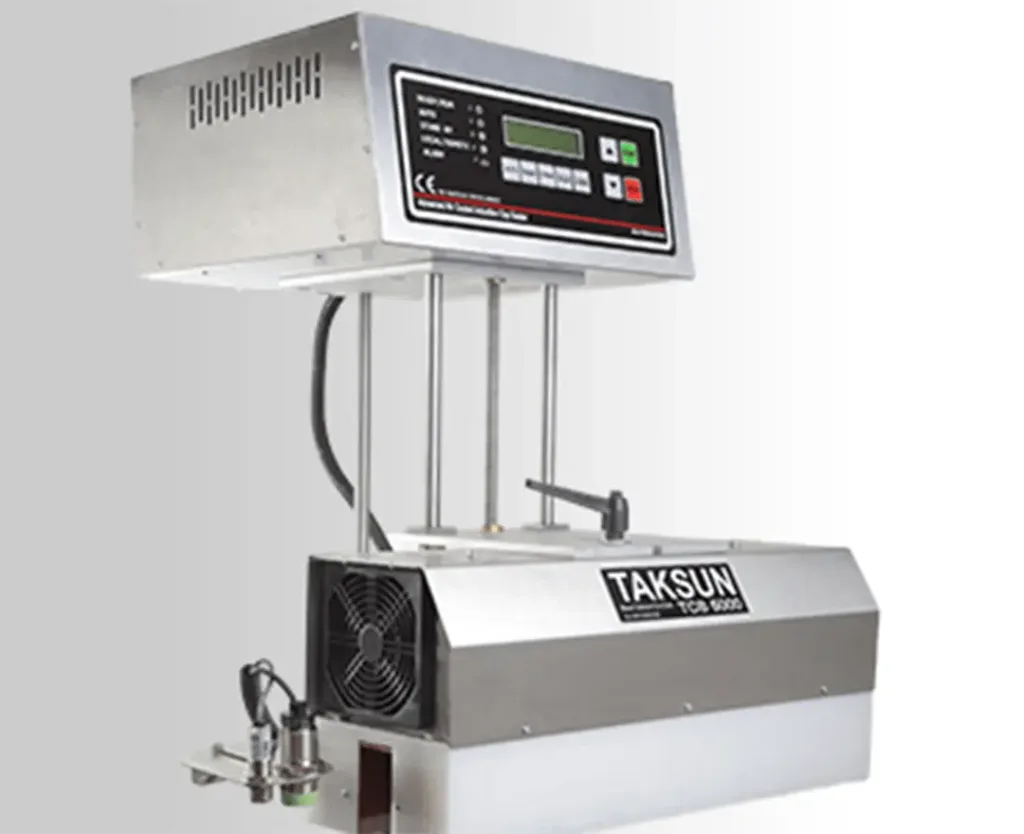

Taksun AutoJr1500 CapSealer

Custom and Unique Design with State-of-the-Art Technology

-

Scratch-resistant full stainless steel body – all cutting and drilling done with laser

Body material -

2-year unconditional warranty and 10 years of after-sales service

Warranty -

Manual height adjustment for bottles of all sizes

Movable head -

Advanced MOSFET circuit with high efficiency and long lifespan

Cutting-edge technology -

Precise timing from 0.1 to 10.0 seconds / Counter up to 9999 bottles

Digital timer/counter -

Ability to seal in two ways (via button on the machine and microswitch)

Advanced -

Air-cooled, no water required, and easy to maintain

Waterless operation -

Sealing containers with neck diameters from 15 to 70 millimeters

Sealing range -

Ability to seal up to 1000 units per hour

Seals per hour -

Power cable length: 2 meters

Output cable -

Weight: 10 kilograms

Easy portability -

Input voltage: 220 volts AC

Operates on mains electricity

-

Scratch-resistant full stainless steel body – all cutting and drilling done with laser

Body material -

2-year unconditional warranty and 10 years of after-sales service

Warranty -

Manual height adjustment for bottles of all sizes

Movable head -

Advanced MOSFET circuit with high efficiency and long lifespan

Cutting-edge technology -

Precise timing from 0.1 to 10.0 seconds / Counter up to 9999 bottles

Digital timer/counter -

Ability to seal in two ways (via button on the machine and microswitch)

Advanced -

Air-cooled, no water required, and easy to maintain

Waterless operation -

Sealing containers with neck diameters from 40 to 120 millimeters

Sealing range -

Ability to seal up to 1000 units per hour

Seals per hour -

Power cable length: 2 meters

Output cable -

Weight: 10 kilograms

Easy portability -

Input voltage: 220 volts AC

Operates on mains electricity

To seal products with non-flat, irregular lids, such as bear-shaped or rocket-shaped sauce containers, a semi-automatic perforated machine can be used. The hole in the base of the head is sized to match the diameter of the lid’s base. To seal, adjust the height so that the lid nearly fits into the hole, and set the guide base so that the lid aligns with the microswitch as it enters the hole to initiate the induction sealing process. Alternatively, you can use the button on the machine instead of adjusting the microswitch for sealing.

-

Features a central hole in the head, sized to match the diameter of the lid's base

Container-matched hole -

Scratch-resistant full stainless steel body – all cutting and drilling done with laser

Body material -

2-year unconditional warranty and 10 years of after-sales service

Warranty -

Manual height adjustment for bottles of all sizes

Movable head -

Advanced MOSFET circuit with high efficiency and long lifespan

Cutting-edge technology -

Precise timing from 0.1 to 10.0 seconds / Counter up to 9999 bottles

Digital timer/counter -

Ability to seal in two ways (via button on the machine and microswitch)

Advanced -

Air-cooled, no water required, and easy to maintain

Waterless operation -

Sealing containers with neck diameters from 15 to 70 millimeters

Sealing range -

Ability to seal up to 1000 units per hour

Seals per hour -

Power cable length: 2 meters

Output cable -

Weight: 10 kilograms

Easy portability -

Input voltage: 220 volts AC

Operates on mains electricity

The semi-automatic induction sealing machine is used for sealing products with relatively low production volumes or in environments where conveyor belts cannot be accommodated. This machine is placed on a table or a surface elevated from the ground. To operate the machine, first, adjust the height of the machine head relative to the height of the container (the underside of the machine head should be a few millimeters away from the container’s cap). Then, adjust the machine head so that the marked point underneath the head is aligned with the center of the container’s cap. For aligning the machine head with the cap, use the guide post installed on the machine’s tray. The guide post moves parallel to the tray, allowing containers of various sizes to be placed under the machine. Since the machine is positioned on an elevated surface, moving large containers or gallons for placement under the machine and sealing can become increasingly difficult, leading to operator fatigue. Therefore, this machine is more suited for containers and bottles that are easy to handle and relatively lightweight.

-

PET and polyethylene jars for pharmaceuticals, such as pill and syrup containers, herbal medicines, dietary supplements, oils, topical creams, and more.

-

Containers with non-flat and non-level lids, such as bear-shaped and rocket-shaped sauce containers, as well as some lidless containers like disposable paper cups, PET bottles, polyethylene containers, and unglazed ceramic jugs.

-

Containers for skincare and haircare creams, shampoos, lotions, hygiene detergents up to 4 liters, dental care products, disinfectants, and more

-

Containers for motor oil and antifreeze up to 4 liters, industrial oils up to 4 liters, agricultural pesticides and fertilizers, and generally products that are not excessively large in volume

Do you have any more questions?

Use this section.

An induction sealing machine is a device used for sealing and closing the caps of containers and bottles.

Induction sealing is suitable for all containers with screw-on or push-on lids.

No! The operation of an induction sealing machine is very simple and does not require any special knowledge or expertise.

To perform induction sealing on your container caps, you only need the Texan induction sealing machine and the induction sealing liner (or cap).

What products are induction sealing used for?

- Food products

- Pharmaceutical

- Industrial

- Cosmetic and personal care

- chemical

- Agricultural

Dairy products, pickles, various butters, types of cooking oils, natural beverages, coffee and instant coffee, pickles, vinegar, olives, chocolate, various sauces, dried fruits, legumes, honey, various natural syrups, dried herbs, spices, food powders, herbal extracts, syrups, rock candy, sugar, candy, fruit leather, tea, various pastes, herbal teas, saffron

Types of pills, capsules, syrups, jar creams, therapeutic gels, medicinal powders, disinfectant solutions, dental care products, sutures, various dietary supplements, herbal medicines, and pharmacy-made medicines.

Engine oil, Gear oil, Brake fluid, Engine cleaners, Antifreeze, Fuel additives, Various industrial lubricants, Grease, Radiator cleaners, Various polishing waxes, Anti-rust solutions, Battery water

Various jar creams for skin care, Hair masks, Lotions, Shampoos, Hand and face cleansing gels, Tooth whiteners, Hygiene cleaners, Fruit and vegetable disinfectants

Various emulsifiers, Various solvents, Various alcohols, Glycerin, Various acids, Various oils, Various liquid chemical products such as liquid sulfur, xylene, ketones, Various powdered chemical products

Various pesticides and agricultural fertilizers, emulsified oils, adjuvants, various seeds, amino acids